Solutions and Sustainability

Our electronic solutions support every stage of manufacturing, from wafer fabrication to final assembly, complemented by smart surface films and in-mold electronics solutions.

Engineered for Innovation

We pioneer advanced materials and chemistries that push technology boundaries through sustainable solutions and optimized manufacturing processes.

As the only company offering integrated solutions from semiconductor device fabrication to final assembly, we enhance reliability, reduce costs, and drive sustainability at every stage of electronic system development.

Our unique approach increases profitability and powers the next generation of electronic devices.

Interconnect Connect Reinforce Protect Thermal Management

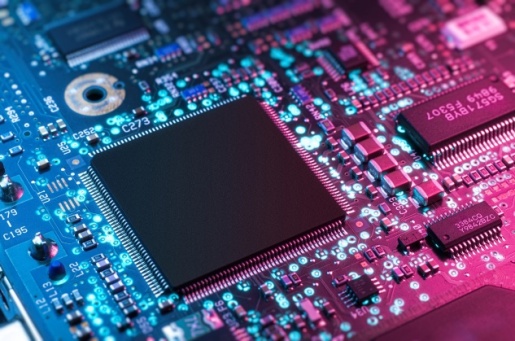

Interconnecting with Precision: Advancing Wafer Level Packaging with Metallization Solutions

Interconnect

Delivering Seamless Electrical Performance

Our advanced interconnect solutions ensure robust and reliable connectivity.integrated metallization technology includes high-precision RDL plating and via filling, void-free fine-feature damascene processes, hybrid bonding, copper pillar plating, and backside metallization.

When applied in wafer-level packaging, PCB fabrication, and semiconductor assembly, our solutions deliver seamless electrical performance and long-term reliability, reinforcing our commitment to innovation and excellence in connectivity.

Connect

Strengthening Circuit Connectivity

We enable reliable circuit pathways that enhance connectivity in high-density designs. Our board-level assembly, circuit fabrication, standard die attach, top-side attach, and package attach solutions create strong, durable bonds with excellent electrical and thermal conductivity for advanced performance.

When applied in circuit board and semiconductor assembly, PCB fabrication, and smart surface applications, these technologies optimize functionality and structural integrity, reinforcing our leadership in electronics manufacturing.

Reinforce

Engineered for Structural Integrity

Our precision bonding technologies reinforce critical components with advanced mechanical and adhesive properties, ensuring reliability and optimal performance in next-generation electronics, even in the harshest of environments.

When applied in circuit board or semiconductor assemblies, our solutions maximize production yield and lower the total cost of ownership, confirming our dedication to the sustainable manufacturing of robust and durable electronic components.

Protect

Optimize Reliability and Performance

Formulated to withstand physical shock, vibration, corrosion, and thermal stress, our protective solutions extend component lifespan and reduce risk of failure.

When used in circuit board assembly, our technologies deliver durable protection and consistent performance, reinforcing our commitment to enhanced device reliability.

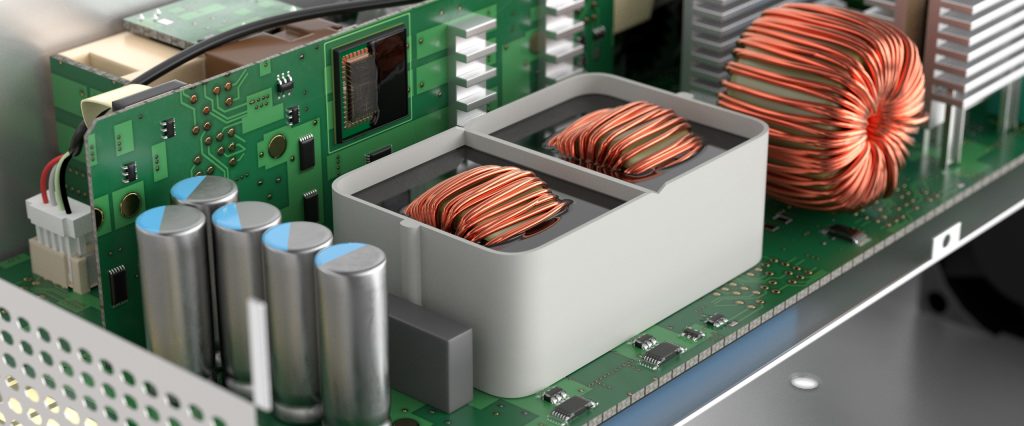

Thermal Management

Superior Thermal Performance

We offer a wide range of thermal interface material (TIM) solutions for circuit board and semiconductor assembly in high-powered electronics, delivering superior thermal performance without compromising device miniaturization or system complexity.

Our combined solutions ensure optimal thermal regulation, reinforcing our expertise in maintaining device efficiency and reliability.

Looking for Solutions?

Boost Performance

Our integrated solutions enhance performance by reducing pitch, supporting 2.5D and 3D packaging, increasing density, achieving 100% throwing power, and enabling heterogeneous integration.

CONTACT US

Optimize Thermal Management

To effectively dissipate heat, it’s important to address thermal challenges across multiple aspects of the assembly. In the image above, we’ve highlighted how our backside metallization and hybrid bonding technologies provide exceptional thermal management.

CONTACT US

Drive Sustainability

We enable sustainable PCB fabrication by meeting RoHS standards, eliminating restricted materials, and reducing resource usage with precious metal-free primary metallization.

CONTACT US

Solutions and Sustainability

Through our global network of R&D and application labs, we provide comprehensive testing, analysis, and validation of solution and application performance.