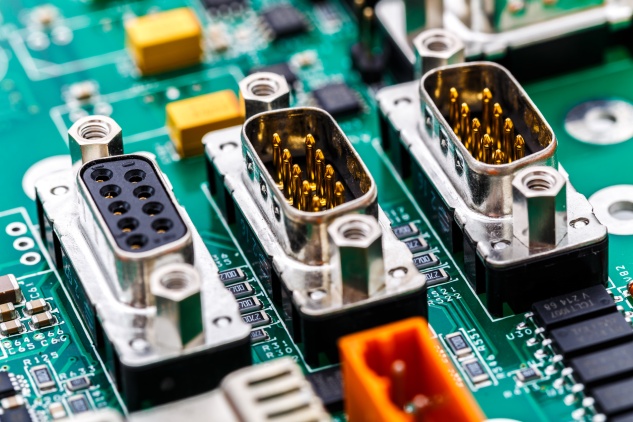

Cored Solder Wire

High-reliability options designed for primary attach and rework applications.

Ensure Superior SIR Reliability

Available in both clean and no-clean options, our cored solder wire ensures superior SIR reliability and excellent spread. Perfect for both manual and automated processes.

ALPHA® Energized Plus Cored Solder Wire

High-Performance RA MIL-SPEC Rosin Cored Solder Wire for Electronic Hand Soldering

ALPHA® Fluitin 1532 Cored Wire

An activated rosin cored solder wire designed for reliable hand soldering and rework, including (SMT) applications.

ALPHA® Telecore HF-850 Cored Wire

Our fastest wetting and lowest spattering, halogen-free and halide-free cored wire offering.

ALPHA® Telecore Plus Cored Wire

A no-clean, low-residue flux-cored solder wire engineered for SMT applications, offering high SIR reliability.

ALPHA® Telecore XL-825 Cored Wire

Cored wire designed to meet JIS Class AA requirements with a halide content <1,000 ppm for no-clean lead-free applications.

Kester® 268 Flux Cored Solder Wire

A zero-halogen flux-cored solder wire optimized for robotic soldering applications.

Kester® 285 RMA Flux Cored Solder Wire

A mildly activated rosin flux-cored solder wire, classified as Type ROL0 under IPC J-STD-004, designed for high-reliability (SMT) and electronic soldering applications.

Kester® 331 Flux Cored Wire

Organic flux featuring a water-soluble formula for use in flux-cored solder wire.

More Products

Kester® AW Flux Cored Solder Wire、Kester® OR-421 Flux Cored Wire

Frequently Asked Questions

How do flux-cored solder wires support high-reliability applications?

Our flux-cored solder wires, available in no-clean, water-soluble, and activated rosin fluxes, are engineered for high-reliability applications. These wires deliver excellent electrochemical performance and form strong, dependable joints even in harsh environments. Available in high-reliability alloys, they further enhance performance, making them ideal for critical assemblies.

What types of soldering applications are flux-cored solder wires suitable for?

Flux-cored solder wires are versatile and suitable for a wide range of soldering applications, including rework and touch-up for both through-hole and surface mount technologies. They deliver consistent performance in automated, robotic, drag, and laser soldering, ensuring reliable and versatile results across various processes.

How do solder wires improve process efficiency and reliability?

Solder wires are designed for efficient, reliable soldering with excellent flux performance and minimal residue. By utilizing high-quality alloys and fluxes, they enhance throughput, reduce rework, and ensure the long-term reliability of assemblies.